GROOVE-90

Thanks to this innovative technology, efficiently producing prefabricated drywall shapes on the construction site as well as in the factory is a breeze.

The continuous development of machine technology is the measure of all things when it comes to pre-formed drywall shapes.

Do you want to produce drywall profiles professionally?

We have the machines and the experience!

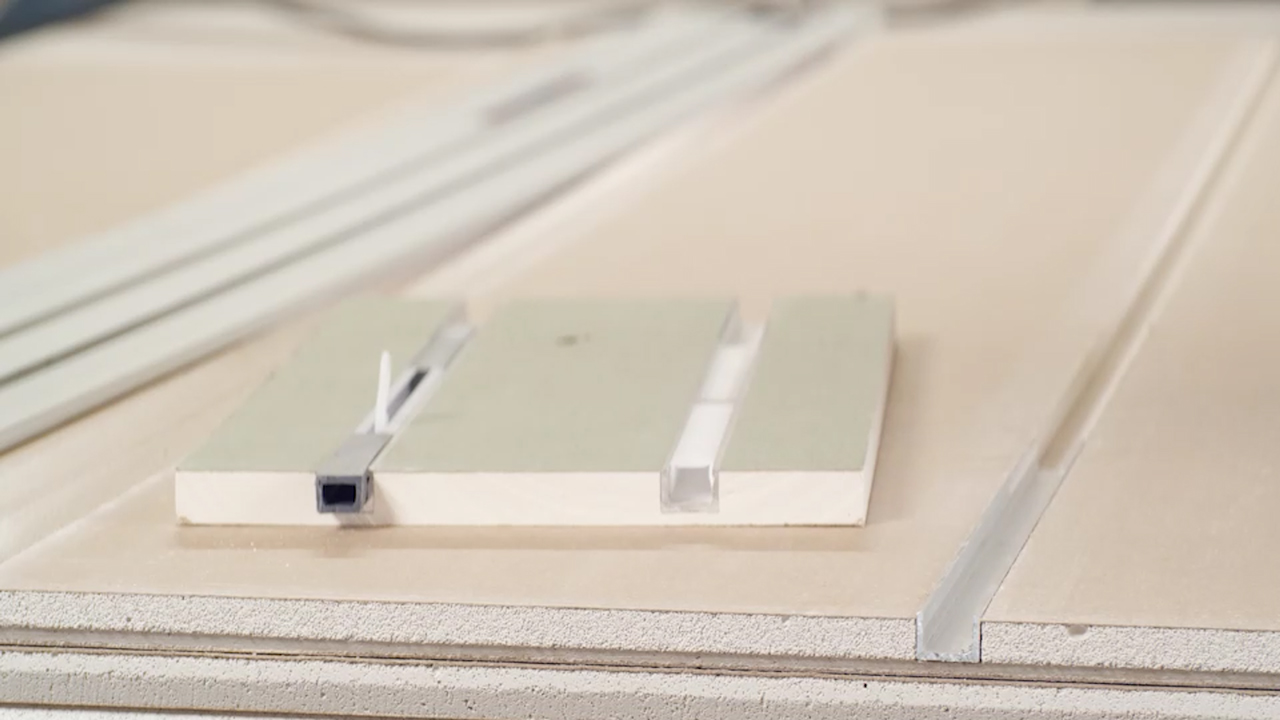

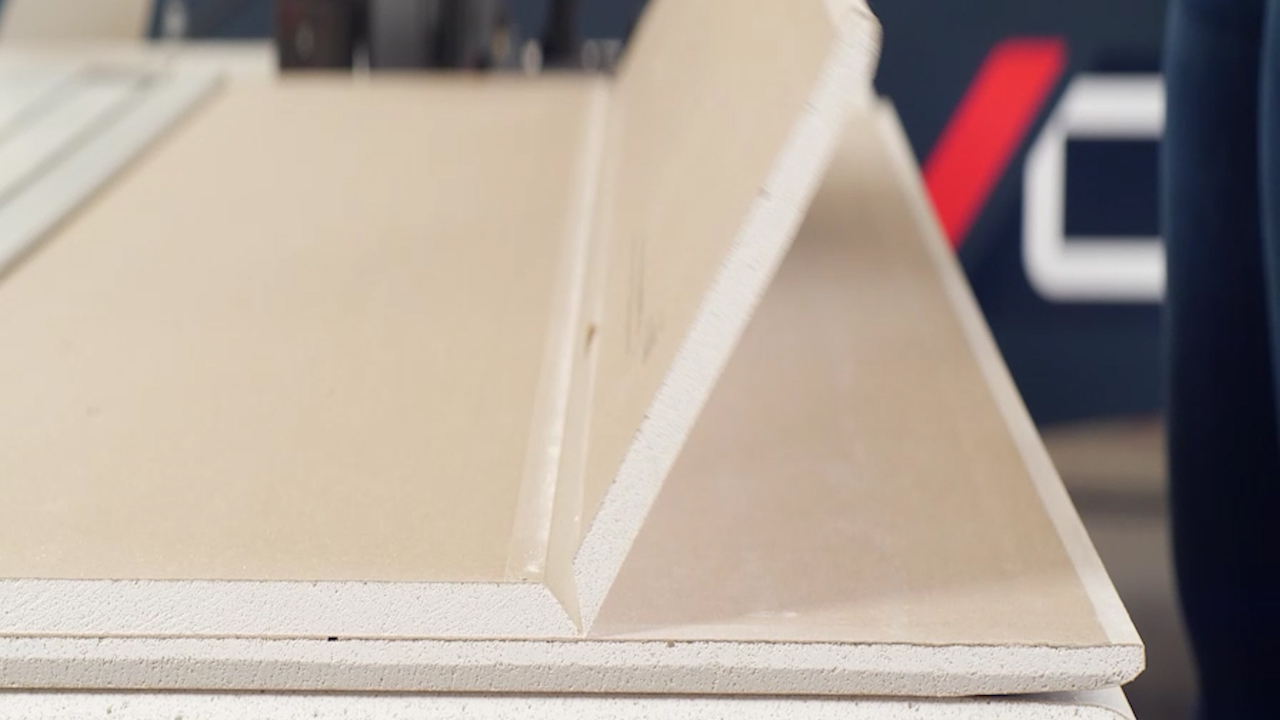

The GROOVE-90 Drywall milling and sawing machine impresses with its precise milling pattern. Thanks to its rotating milling disc, you can cut material out of the panel, creating a sharp edge and a dust-free V-shaped groove. Unlike rotating cutter heads, the groove is ready and clean for gluing.

PRECISE ADJUSTMENT

The milling depth can be adjusted to the nearest millimeter on a scale of 1/10 using an additional set screw.

PRECISION

Additional precision safety – the milling plate runs along the material surface, which prevents tipping and provides the GROOVE-90 with a secure position even when used in conjunction with a guide rail.

SAFETY

You can open the protective cover in a single movement. The power-on lock and blade lock are both activated automatically when you open the protective cover.

GROOVE-90

Advantages:

- Longitudinal and transverse grooves (e.g. for LED profiles)

- V-grooves (90° and 45°) for drywall shapes

- Milling edge technology for the processing of aluminum composite panels (ALUCOBOND®)

- Materials that can be used: solid wood, MDF, drywall, aluminum composite panels

- • Multi saw unit to create round columns

- Sawing Depth: 0 – 26 mm

- Milling Depth 0 – 17 mm

- Nominal idle speed: 3,600 – 6,250 1/min

- Universal motor: 230 V / 50 Hz and 110V / 60 Hz

- Rated power: 1,400 W

- Weight: 4.9 kg

- 1 parallel fence

- 2 position indicators

- HM saw blade 120 x 1.2/1.8 x 20 mm, FZ/TR

- 1 guide rail 160 cm / 210 cm (optional, depending on requirements)

- 1 guide rail 160 cm / 210 cm (optional, depending on requirements)

- 1 guide rail connector, where applicable